Lab Instruments

C.W. Brabender Plasticorder® with a Banbury mixer

Melt blending is a dispersive technique that involves the intimate mixing of an additive into the polymeric matrix. It requires a physical change in the polymer, i.e. the polymer has to be in the molten, or rubbery, state during mixing, and it necessitates high shear forces to bring about the mixing. Obtaining the proper viscosity is the key to the successful operation of the Brabender and fabrication of a uniformly dispersed composite.

Carver Press equipped with a heating element

Samples can be compression molded to obtain the shape and dimensions needed for specific mechanical and thermal tests, such as those needed for dynamic mechanical analysis (DMA) and dielectric analysis (DEA). [Top]

TA Instruments Dielectric Analyzer DEA 2970

Dielectric analysis is a technique used to determine the molecular motions and structural relaxations present in materials possessing permanent dipole moments. It measures the electrical response of a material with respect to time, temperature and frequency. Capacitance and conductance are measured to obtain the dielectric constant, or permittivity (ε') which is proportional to the capacitance, and the dielectric loss (ε'') which is proportional to the conductance. Unlike DSC, DEA can be used to identify the secondary relaxations present in a polymer as long as the secondary group has a net dipole moment. DEA can also be used to monitor cure kinetics, resin flow and ionic conductivity.

The DEA can accommodate testing of various forms of samples, i.e. gels, liquids, solids, powder, and thin films. Four types of sensors exist for the TA Instruments DEA: parallel plate, single surface, sputter coated and remote single surface. Measurements can be taken within a temperature range of -150 ºC to 500 ºC and through a frequency range of 0.1 - 100k Hz. [Top]

TA Instruments Differential Scanning Calorimetry DSC 2910

Differential scanning calorimetry (DSC) is a powerful thermal analysis technique used to measure the heat fluxes emitted or absorbed by a sample as a function of temperature and time. When a thermal transition occurs the enthalpy change is recorded. In addition to measuring the basic phase changes like the glass transition temperature (Tg) and melt temperature (Tm) other valuable quantitative properties can be determined. These include, but are not limited to, percent crystallinity, heats of crystallization and fusion in semi-amorphous polymers and organic-inorganic compounds, degree of cure and reaction kinetics in thermosets, oxidative stability, thermal conductivity, decomposition and crosslinking. DSC is a versatile technique that can be used for polymer, organic and inorganic analysis, of which the sample can be in the form of a solid, liquid or gel.

The experiment is run under an inert atmosphere, using dry argon, helium or nitrogen gas with a flow rate of ca. 50ml/min. The DSC can be configured to run from sub-ambient temperatures with the aide of a liquid nitrogen cooling accessory (a.k.a. LNCA) or the DSC cooling can. Experimental data collection may encompass a temperature range of -150 to 725ºC. [Top]

TA Instruments Dynamic Mechanical Analysis DMA 2980

Dynamic mechanical analysis (DMA) is used to measure the viscoelastic properties of materials. When an oscillating stress, or load, is applied to a material it will respond by deforming sinusoidally. This deformation, or strain, will depend on how much viscous and elastic behavior the material possesses. When a 100% elastic material at its Hookean limit is subjected to a stress it will respond by deforming in an in-phase sine wave strain (no time lag, δ= 0º). When the stress is removed it will return to its original shape. When a 100% viscous material is subjected to a stress it will respond by deforming in an out of phase sine wave (δ = 90º). When the stress is removed it will not return to its original shape. Polymers, on the other hand, exhibit a combinatorial time dependent response that is visco-elastic. The strain that is recovered in the polymer is a result of the elastic properties and the strain that is not recovered is a result of the viscous properties of the material; the phase shift angle will be between 0º and 90º.Viscoelastic measurements are therefore used to determine the internal structure of the material and can be used to investigate structure-property relationships. In DMA, the modulus is measured with respect to time, temperature and frequency. The TA Instruments DMA 2980 can record measurements within the temperature range of -150 ºC to 500 ºC and within a frequency range of 0.1Hz to 100Hz.[Top]

TA Instruments Rheometer AR 2000

The TA Instrument Rheometer allows for controlled stress and controlled strain measurements. The design of the rheometer allows for great controlled stress, direct strain and controlled rate performance. A wide variety of measurement can be taken using the AR 2000 such as, characterization of delicate structures in fluids of any viscosity, polymer melts, solids, and reactive materials. [Top]

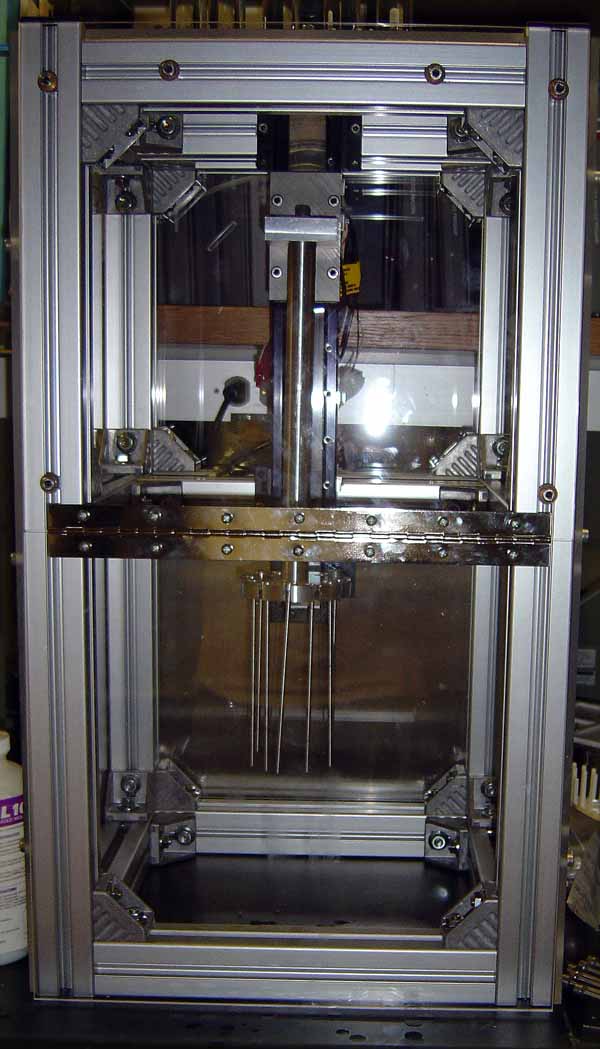

Controlled Rate Dip Coater

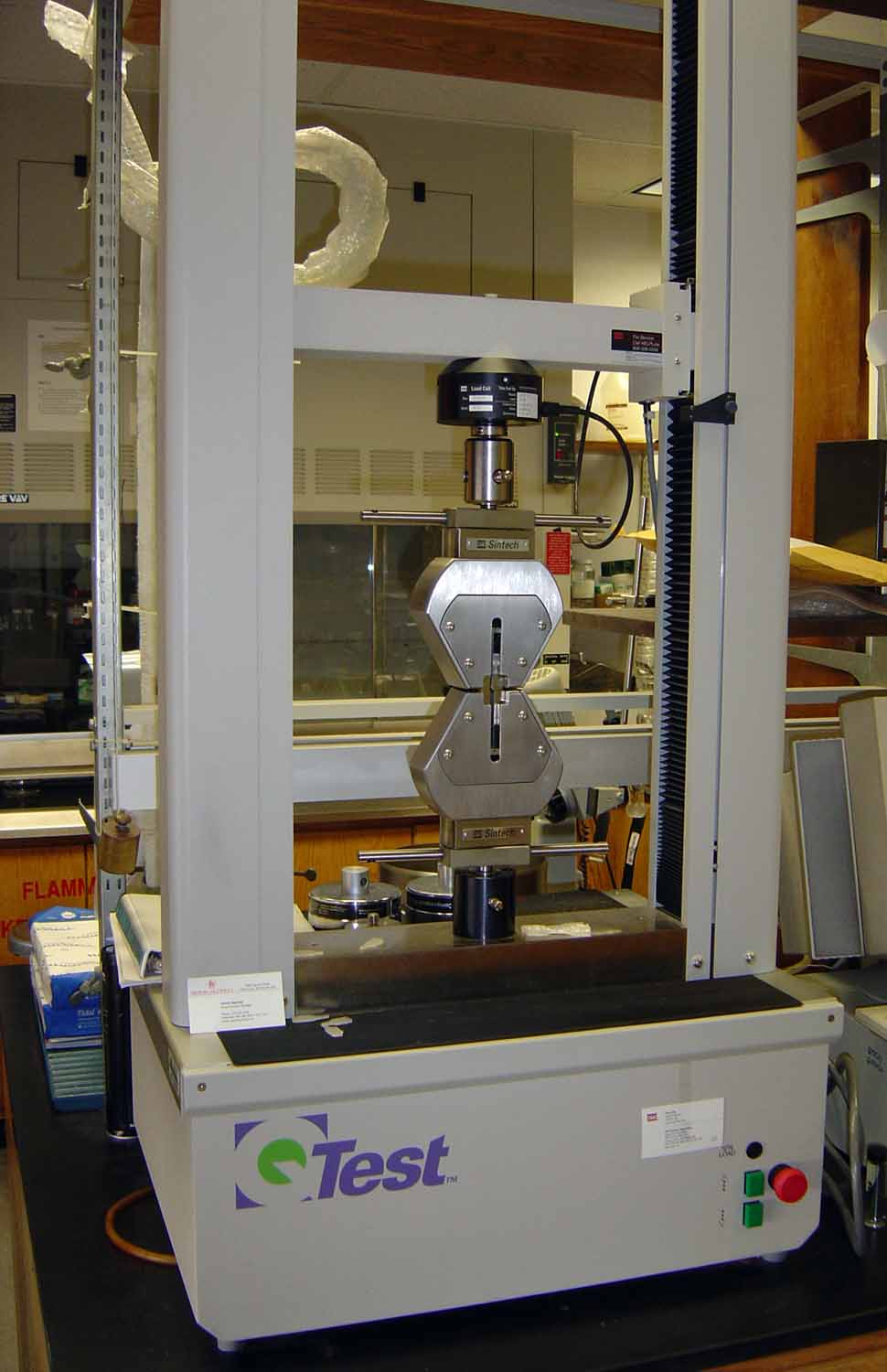

Q Test Tensiometer

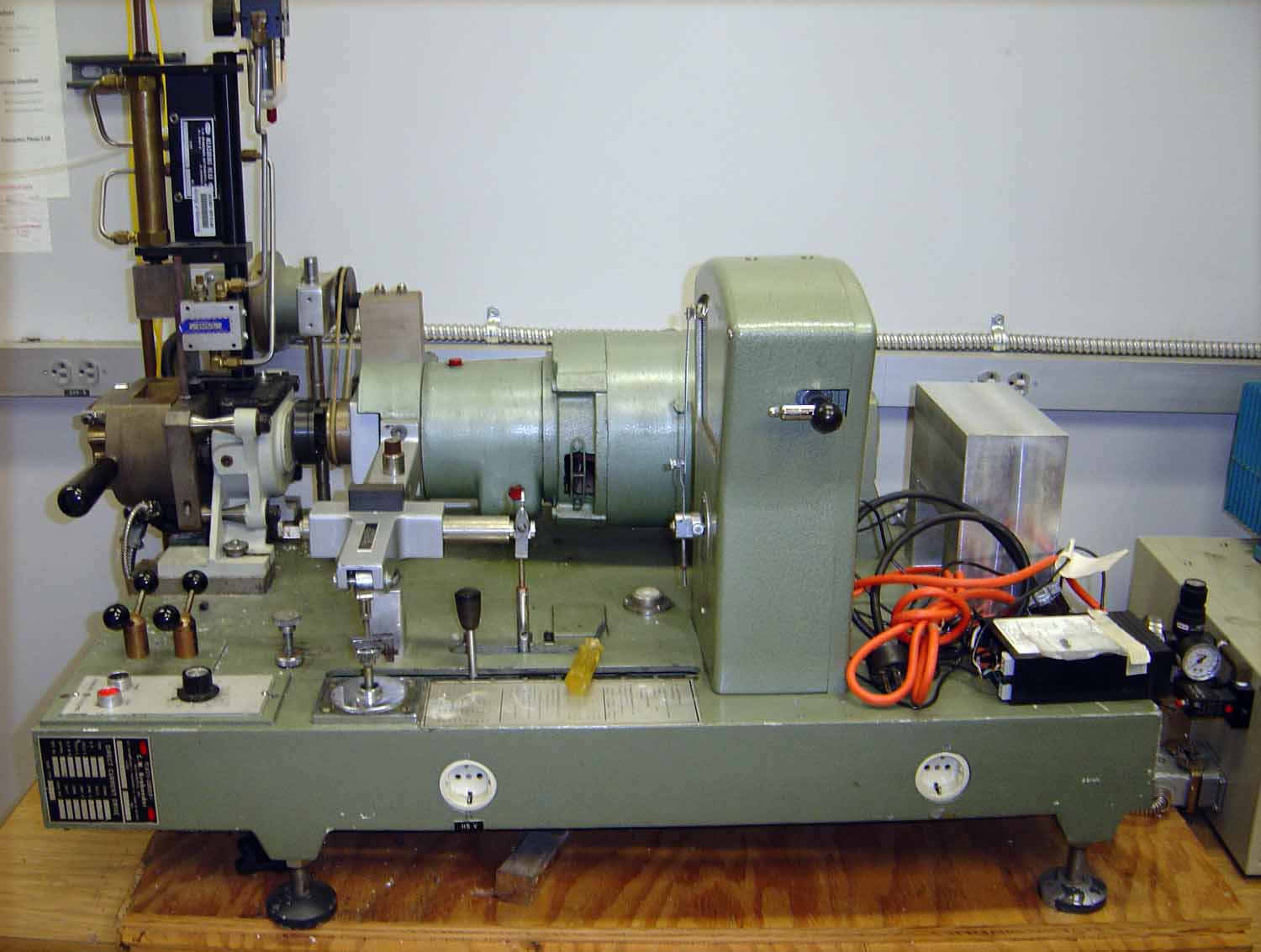

Custom Scientific Instrument Fibercaster

Buchi Rotovapor

Wigglebug

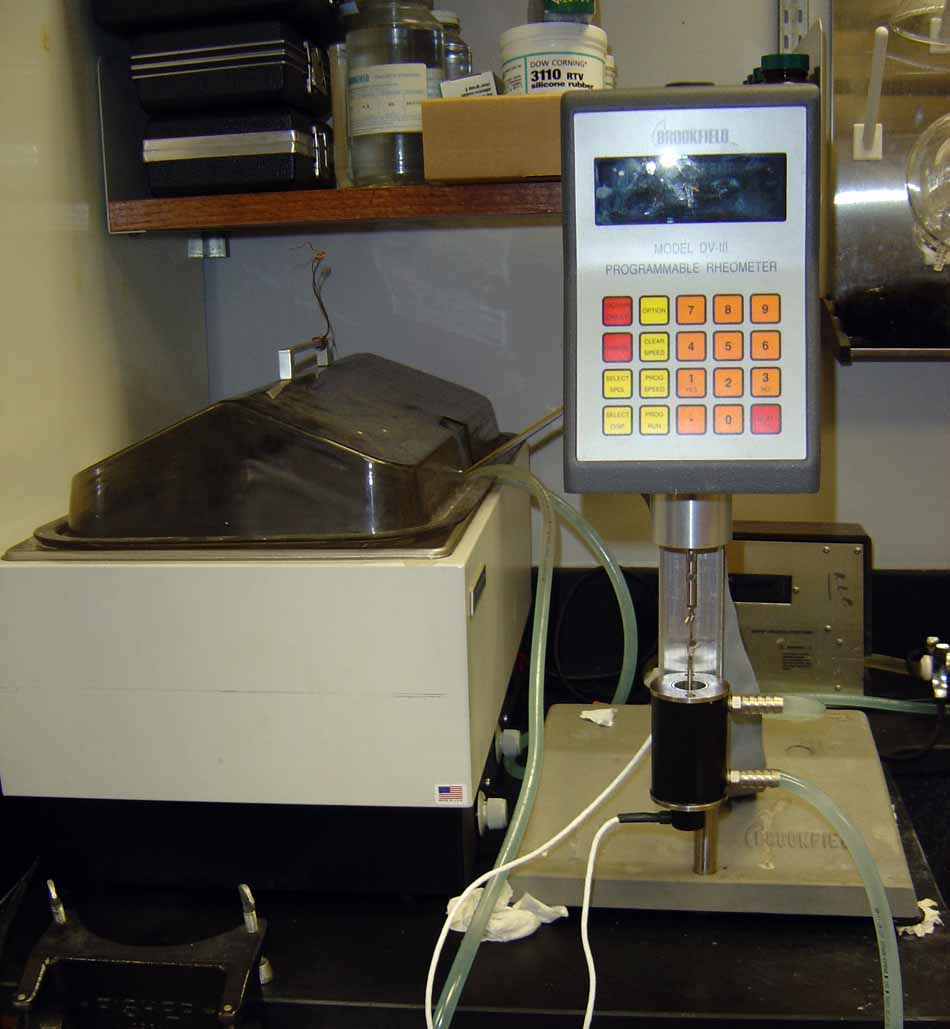

Brookfield Programmable Rheometer

HP Diode Array Spectrometer

The UV Vis allows for the molar absorptivity and the maximum wavelength (lambda max) to be determined from the absorbance or transmittance readings given. The absorbance and transmittance readings are read from the amount of light that is either absorbed or reflected. The UV Vis scans the wavelength from 200nm to 800nm. [Top]

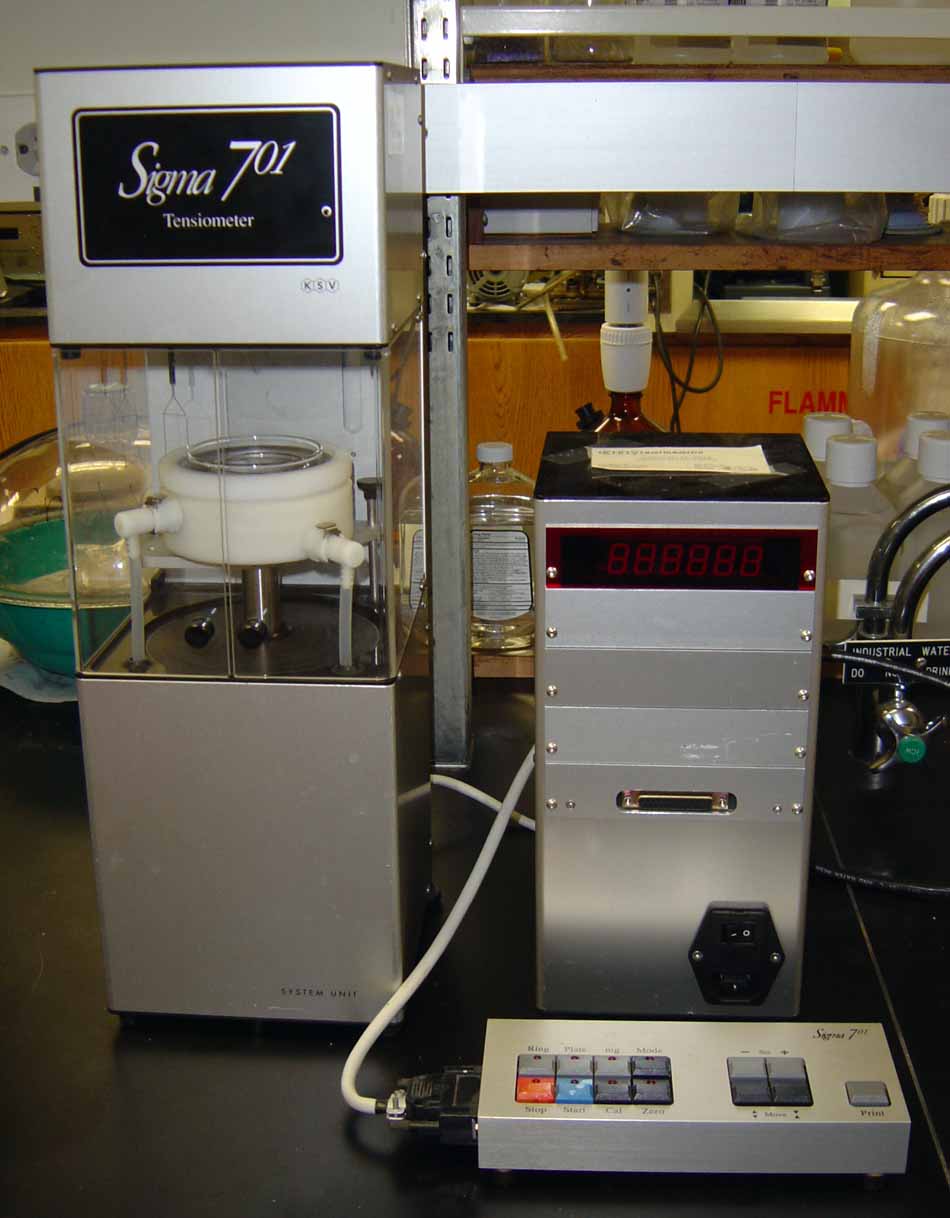

Sigma Tensiometer

Branson Sonifier 450

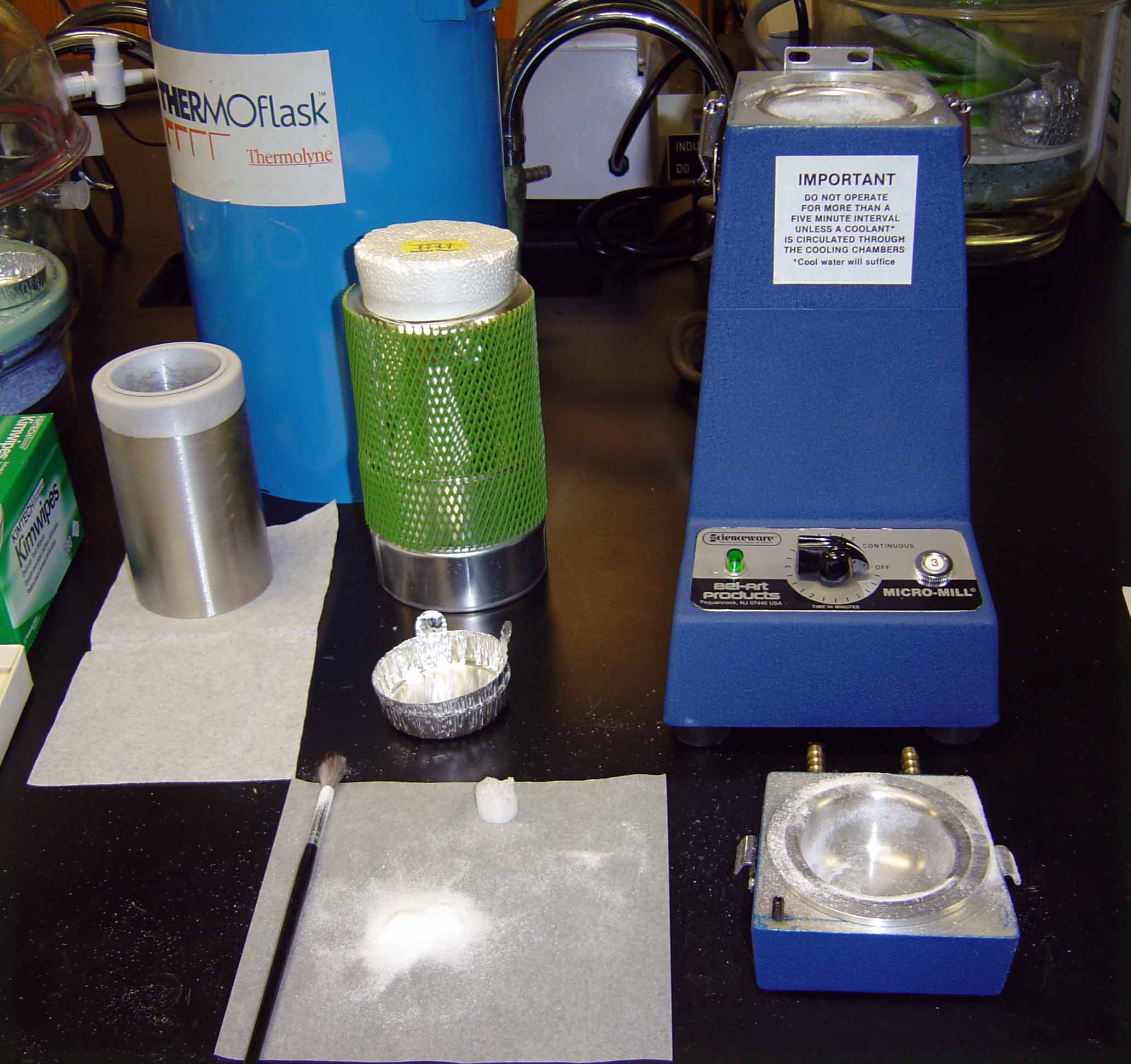

Belart Micromill Grinder

Spincoater

Morgan Press

[Top]